Laser Cleaning Services

Solutions

Rust Removal

Flash rust removal leaving the underlying metal surface clean and free of corrosion. Thin layers or rust disappear at high speeds. Ready for inspection and refinishing.

Non-Destructive Testing (NDT)

Non-destructive testing, (NDT) Laser cleans and preps metal surfaces for better readings and more accurate inspections.

Oils and Grease

Clean oils and greases from various surfaces. Laser vaporizes the oils and greases, leaving the surface clean and free of contaminants.

Turbine Maintenance

Laser has proven to be the best technology to clean turbine parts without damaging the substrate, compared to glass, sand or dry ice blasting.

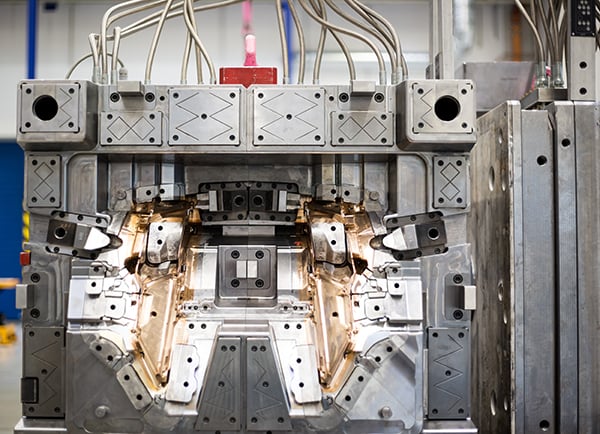

Plastic injection mold cleaning

Safe cleaning of your valuable moulds. No secondary waste or damage to the substrate – safe for high gloss finish and base materials.

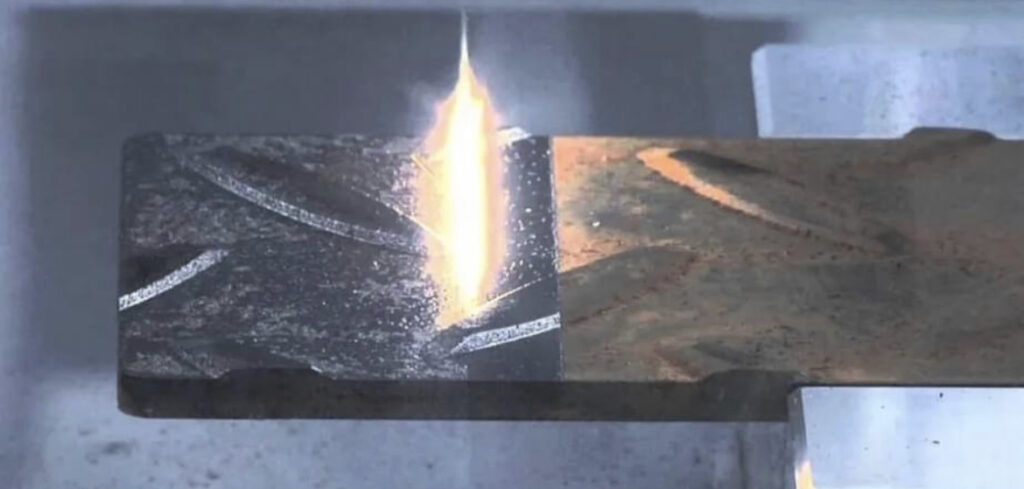

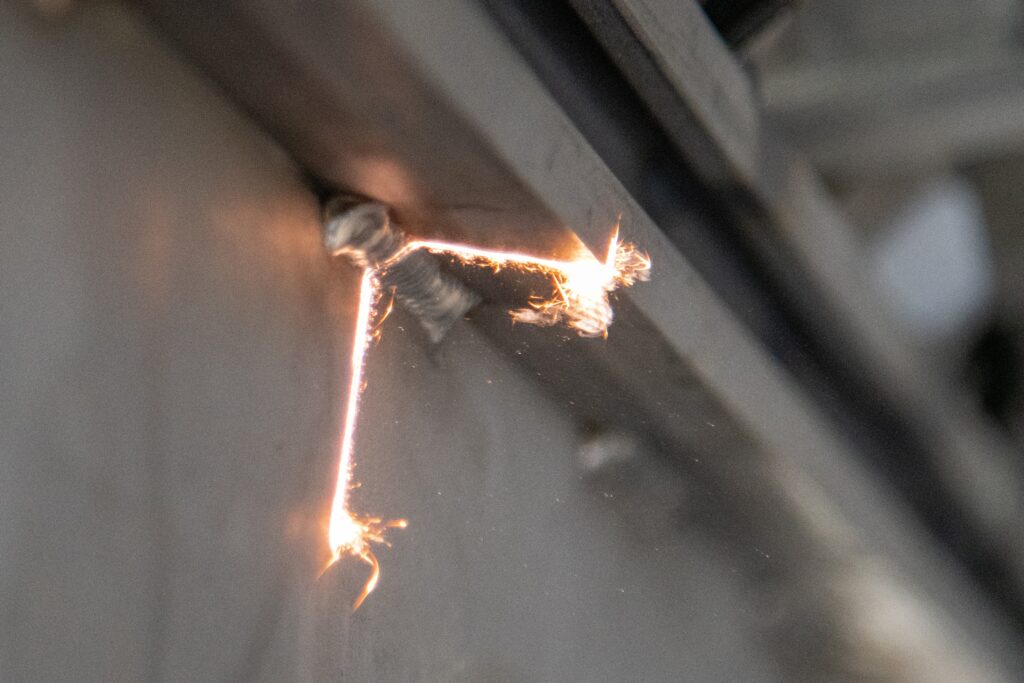

Oxide Layers

Removing oxides after welding, without using chemicals. Laser cleaning also allows for weld preparation and drastically decreases the number of imperfections in the weld.

Selective Painted Surfaces and Coatings

Coatings come in all colours and varieties imaginable; making it a challenging but fascinating application. We have cleaned many types of coatings.

Smoke Stains, Concrete, Brick

Although we prefer metals, it can be virtually anything. As long as it can withstand heating and it should have some reflective capacity, it is worth testing.

Parts Repurposing and Rejuvenation

Laser cleaning is an excellent method to restore antiques due to our ability to fine-tune the laser strength, providing unmatched results when compared to legacy restoration methods.

Why Choose Us

We have over 20 years of Construction and Industrial experience and are dedicated to delivering top-notch services to meet your cleaning needs. We work closely with our clients to understand their requirements and provide customized solutions that best fit their specific needs.

So, if you’re looking for a reliable and effective cleaning solution, look no further! Let us help you make your world a cleaner and brighter place. Contact us today to learn more about our laser cleaning services and how we can help you.

FAQS

How does laser cleaning work?

Laser cleaning works according to the principle of pulsed laser ablation. We add a lot of energy to the surface in the form of light in a very short period of time (nanoseconds). The light will be absorbed by the contaminant and will reflect on the substrate. In between the substrate and the contaminant, a layer of gas will be created which pushes the contaminant away from the substrate. Minimal evaporation is possible. The combination of these processes is called ablation.

Which materials can be cleaned with a laser?

The results are particularly good with metal substrates, with a variety of alloys, such as aluminum, machine carbon steel, copper, stainless steel, etc. Mineral substrates like stone and concrete can be cleaned as well, but the results will differ depending on the contaminant. Wood and other heat-absorbing materials like plastic are not recommendable.

Which substances can be removed with laser cleaning?

We can remove a lot of organic and anorganic substances with a laser, such as grease, oxide, coatings (paint), etc. Do you have a specific question or a challenging project? Send us your case via [email protected], chances are that we already have experience with your problem!

Does laser cleaning damage the substrate?

No, one of the big advantages of laser cleaning is that it doesn’t damage the substrate when used correctly. You can clean your delicate and expensive substrates without having to worry.

Does laser cleaning heat up the substrate?

Laser cleaning will slightly heat up the substrate, but this heating up will be minimal, since a pulsed laser beam is used for laser cleaning. The pulses of light are so short that the substrate doesn’t heat up, or only heats up slightly (depending on the material of the substrate of course).

Does laser cleaning leave behind waste residue?

No. Laser cleaning does not generate secondary waste. The results are so clean, that we can remove visible finger prints from stainless steel!

Is laser cleaning harmful to the environment?

No, not at all. Laser cleaning works with pure light, and does not add harmful chemicals to the process. No secondary waste is created like with sand blasting, where the sand that is used to clean is contaminated, and needs to be cleaned up afterwards. With laser cleaning, the contamination that is released is immediately captured and collected, and can be safely deposited afterwards. The amount of waste is therefore minimal.